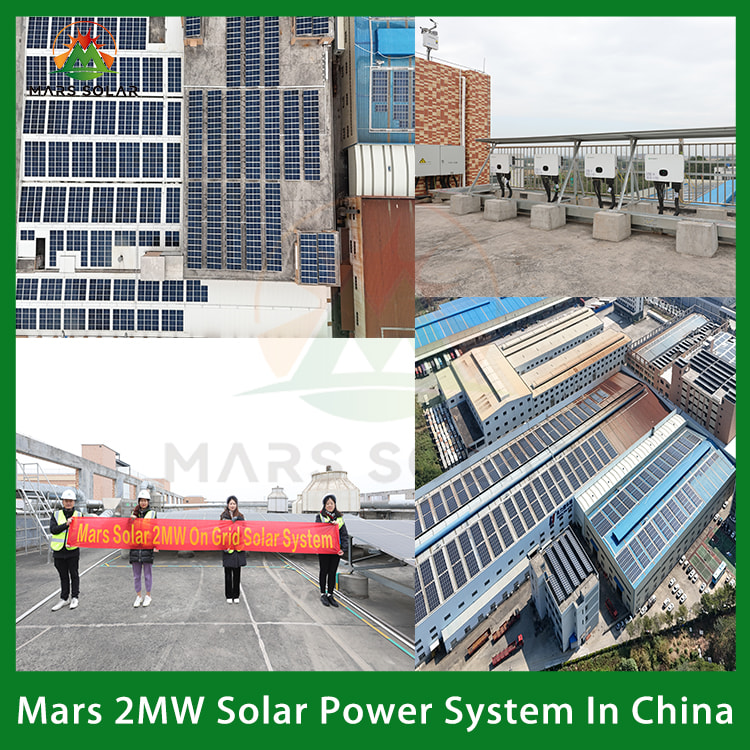

2MW mars solar grid-tied solar panel system for factory have designed, produced, and installed in a factory.How does Mars Solar build such a solar panel system for factory?

1. Data collection

Before designing the plan, the factory owner visited Mars solar factory to gain a detailed understanding of MARS SOLAR product production, quality control, and project experience. Through conversation, it was learned that the factory works timing, with a high degree of mechanization and high electricity consumption.

The county where the factory is located has a photovoltaic power sales policy, so the factory owner is considering installing more solar panels to sell excess electricity to the national power grid while ensuring the electricity supply of their factory, in order to reduce electricity bills at night.

This solar panel system for factory design fully considers these factor:

The factory consumption in this time and consumption for the future.

Monthly electricity bill, through which the peak and average electricity consumption can be calculated, and the required system coverage for electricity consumption can be determined

Another factors like solar panel installation space,transformer capacity etc.

2. On site measurement of installation area

Through on-site measurements, we calculated the total area which can install solar panel. After subtracting the area with weaker lighting, the remaining area can with an estimated total power of 2MW.

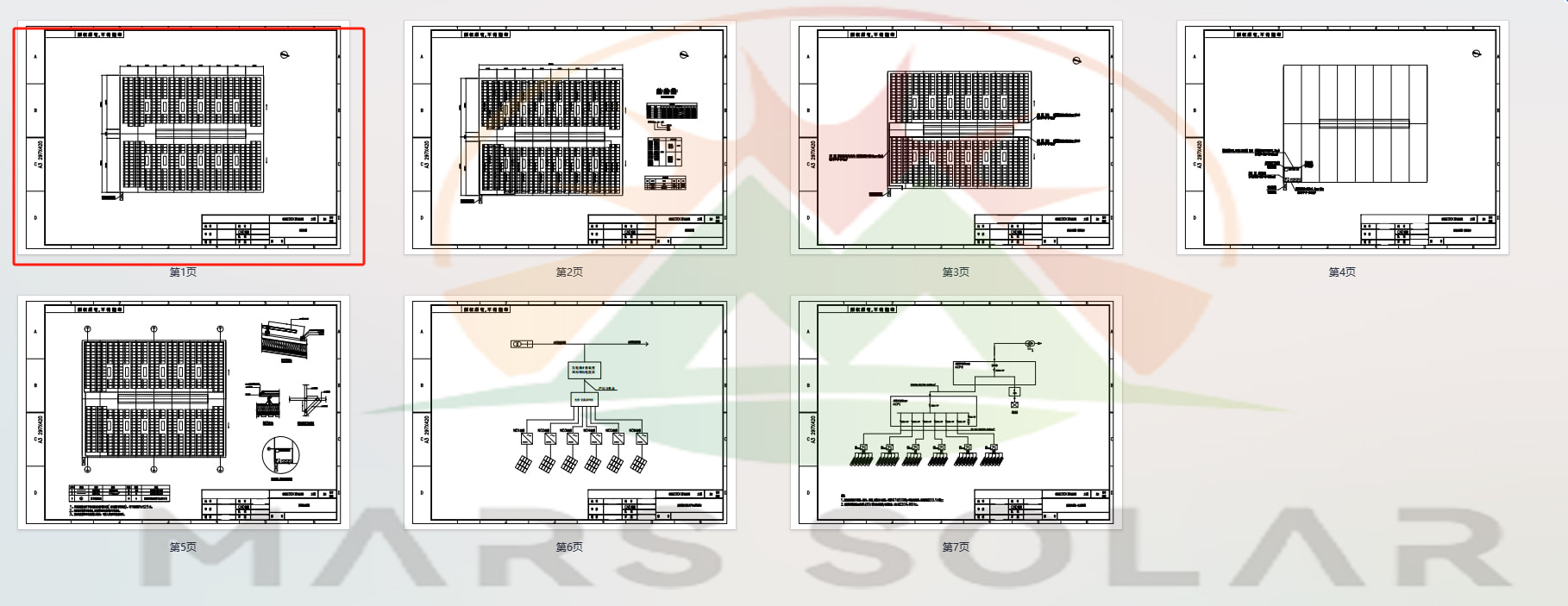

3. Design the solar panels layout

This factory is located at 23 degrees north latitude, so the best inclination angle for installing a flat cement roof is around 23 degrees. For flat roof installation, 40 * 40cm cement piers are used and placed directly according to the design points for installing support columns.

Mars solar not only provides the necessary quantity for the support design and configuration of each solar panel system for factory project, but also gives away 2-3% of accessories to customers as a gift to ensure that the construction period will not be delayed due to accessory reasons during the construction process.

4. Return on Investment Report (ROI)

Using NASA's climate data, calculate the power generation determined by this industrial solar power plant system. Ensure the return on investment for customers.

The 2MW industrial solar power plant project has an expected investment return time of 4 years for the owner, which means that starting from 2027, the industrial solar power plant will start using free electricity and be able to generate revenue from selling solar energy systems.

5. Determine the proposal

After discussion and investment return calculation, the factory owner expressed satisfaction with the industrial solar power plant, two companies signed a contract and began arranging production.

6. Production

After the contract is signed, mars solar immediately start production, strictly following the IEC61730 and ISO9001 standards. We ensure that each solar panel uses LonGi cells and undergoes 100% EL testing 4 times, fully complying with the IEC61730 standard, to ensure efficient power generation and long service life of the solar panel

7. Installation

The installation of the grid connected industrial solar power plant project starts with the brackets. We divided into two teams to construct the sloping roof and flat roof respectively.The industrial solar power plant project installation have been completed in 31 days.

This industrial solar power plant project adopts 380V low-voltage grid connection, so no step-up transformer is required.The inverter of this project is installed outdoors using a rain shelter, which has the main benefits of reducing operating temperature and minimizing photovoltaic line losses

8. Acceptance

After the completion of the industrial solar power plant project, we will assist the client in providing necessary documents, successfully completing the acceptance, grid connection, and starting power generation.

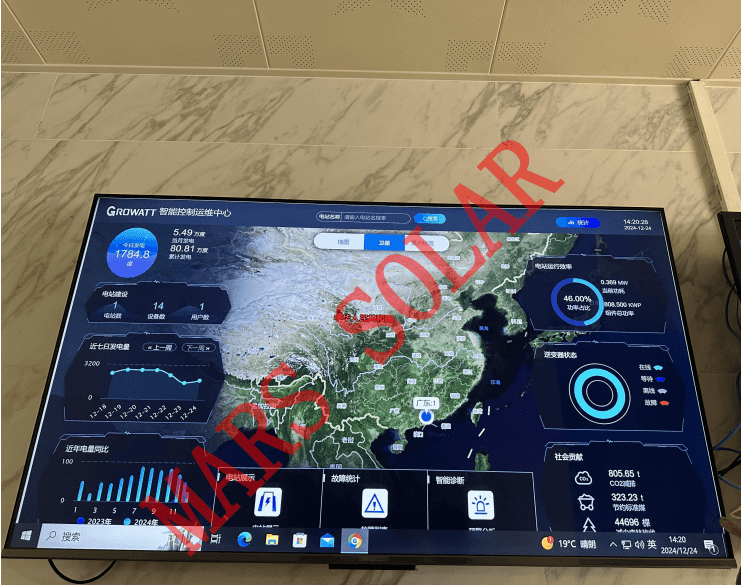

9. Visualization of System Operation(IOT)

By collecting data from various inverter, we can not only view the power generation information of the power station on the operation and maintenance platform, but also display the data in the lobby of the factory, making it convenient for owners to view real-time power generation data.

The grid connected industrial solar power plant system supports viewing power generation status, including power generation, fault causes, and fault resolution methods through mobile and web clients, providing efficient support for after-sales service, reducing after-sales time and service costs.

As of December 2024,this industrial solar power plant has generated a total of 2020250 kWh of electricity, reducing 49995 tons of carbon emissions for society, equivalent to planting 110633 trees.

10. Post maintenance

1) Regular cleaning of solar panels can increase their power generation, reduce heat spot effects, and extend their lifespan. By directing the water source to the rooftop, the cleaning of solar panels becomes easier. It is recommended to clean areas with high dust levels at least once a month, while other areas can be cleaned every three months

2) Annual inspection, mars solar provides an annual inspection, including but not limited to: wiring inspection, power generation data inspection, bracket and bridge rust prevention inspection, as well as inverter fan operation inspection, etc., to provide lifelong service for customers' power plants

Mars solar has been committed to providing customers with one-stop services from design, production, shipping, and installation for 17 years. Please feel free to contact us. As long as you tell us your needs, we will have a professional team to provide one-on-one services for your industrial solar power plant project.

-

Case Study: 200kW Solar Power System Project for a Rice Mill in a Remote Area ofProject Overview This is a rice mill located in a remote area of Abuja, Nigeria. The local municipal power supply is unstable, and electricity tariffs have increased multiple times this year. Due to the unreliable grid power, the customer can only oper

Case Study: 200kW Solar Power System Project for a Rice Mill in a Remote Area ofProject Overview This is a rice mill located in a remote area of Abuja, Nigeria. The local municipal power supply is unstable, and electricity tariffs have increased multiple times this year. Due to the unreliable grid power, the customer can only operDo you like ?0

Read more -

Solar PV System Expansion: Compatibility, Efficiency & Implementation Guide1. Background and Necessity Early-installed PV systems generally fail to meet the growing energy demands of modern households and enterprises. Compared with replacing the entire system, expansion is a more economical option—but the core question

Solar PV System Expansion: Compatibility, Efficiency & Implementation Guide1. Background and Necessity Early-installed PV systems generally fail to meet the growing energy demands of modern households and enterprises. Compared with replacing the entire system, expansion is a more economical option—but the core questionDo you like ?0

Read more -

Customized Off-Grid Solar System for a Liberian Bank: Achieving Power IndependenWhen Banks Face the Challenge of "Grid Power Outages and Voltage Fluctuations": A Real-World Solution from Liberia In scenarios where the power grid is unstable and manual intervention is difficult, how to ensure the 24/7 stable operation

Customized Off-Grid Solar System for a Liberian Bank: Achieving Power IndependenWhen Banks Face the Challenge of "Grid Power Outages and Voltage Fluctuations": A Real-World Solution from Liberia In scenarios where the power grid is unstable and manual intervention is difficult, how to ensure the 24/7 stable operationDo you like ?0

Read more -

2MW Solar Panel System For Factory2MW mars solar grid-tied solar panel system for factory have designed, produced, and installed in a factory.How does Mars Solar build such a solar panel system for factory? 1. Data collection Before designing the plan, the factory owner vi

2MW Solar Panel System For Factory2MW mars solar grid-tied solar panel system for factory have designed, produced, and installed in a factory.How does Mars Solar build such a solar panel system for factory? 1. Data collection Before designing the plan, the factory owner viDo you like ?0

Read more -

100KW Solar For Hotels And Resorts In NigeriaIn December 2024, the Mars Solar 100KW Nigeria solar for hotels and resorts project was successfully completed. In May 2024, the customer contacted Mars solar and had a series of communications on the solar for hotels and resorts project. The d

100KW Solar For Hotels And Resorts In NigeriaIn December 2024, the Mars Solar 100KW Nigeria solar for hotels and resorts project was successfully completed. In May 2024, the customer contacted Mars solar and had a series of communications on the solar for hotels and resorts project. The dDo you like ?0

Read more -

Reliable Energy Solutions for a Mali Pharmacy: 15KW Solar System Success StoryIn the heart of Mali, reliable electricity is a significant challenge, with power coming on for just 2 hours and then cutting off for 4 hours multiple times a day. This erratic power supply is particularly problematic for businesses that depend on consist

Reliable Energy Solutions for a Mali Pharmacy: 15KW Solar System Success StoryIn the heart of Mali, reliable electricity is a significant challenge, with power coming on for just 2 hours and then cutting off for 4 hours multiple times a day. This erratic power supply is particularly problematic for businesses that depend on consistDo you like ?0

Read more